Our Products

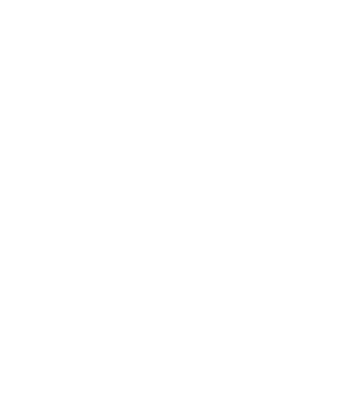

Washed Activated Carbon

Washed Activated Carbon

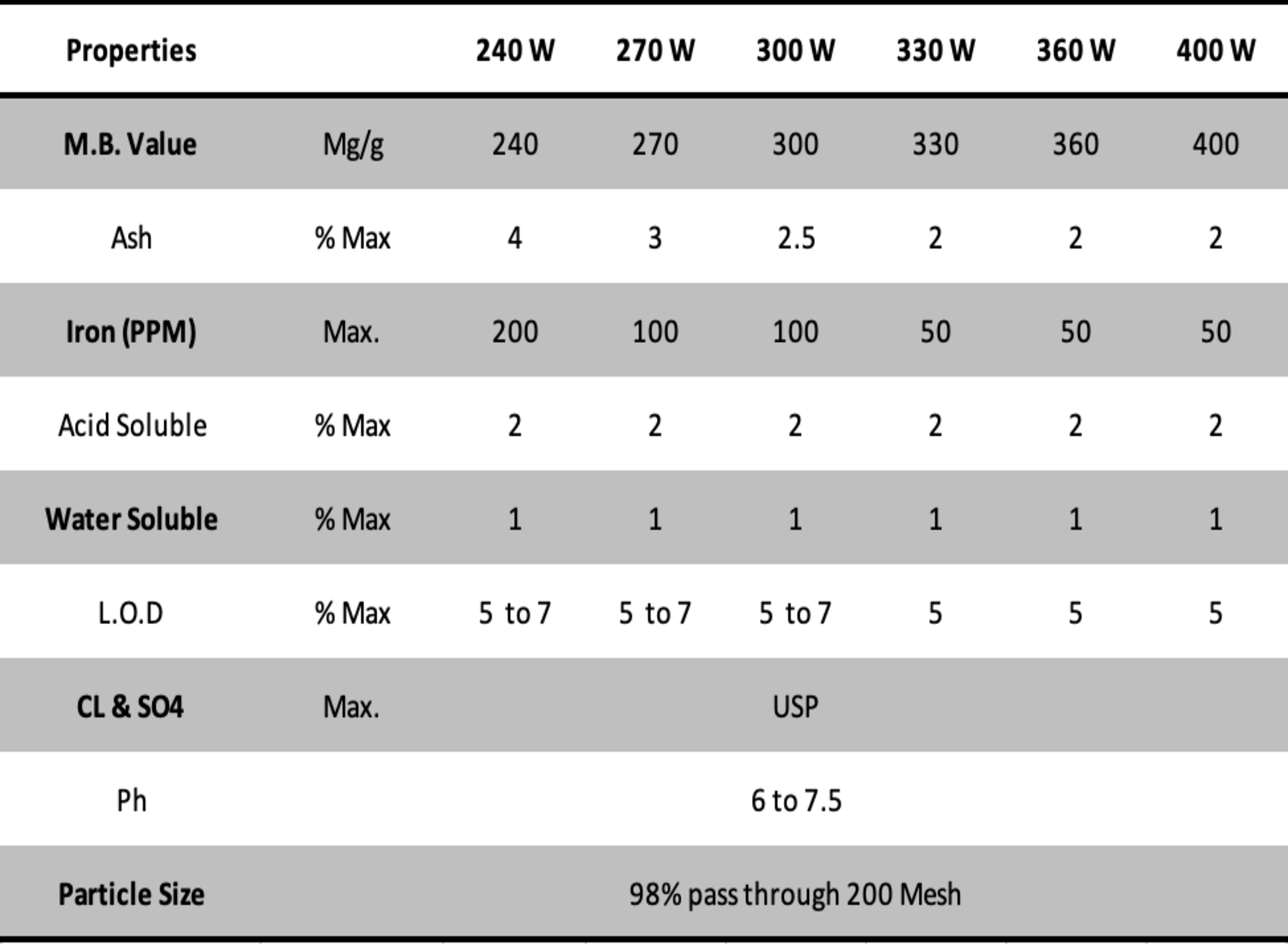

Unwashed Activated Carbon

Unwashed Activated Carbon

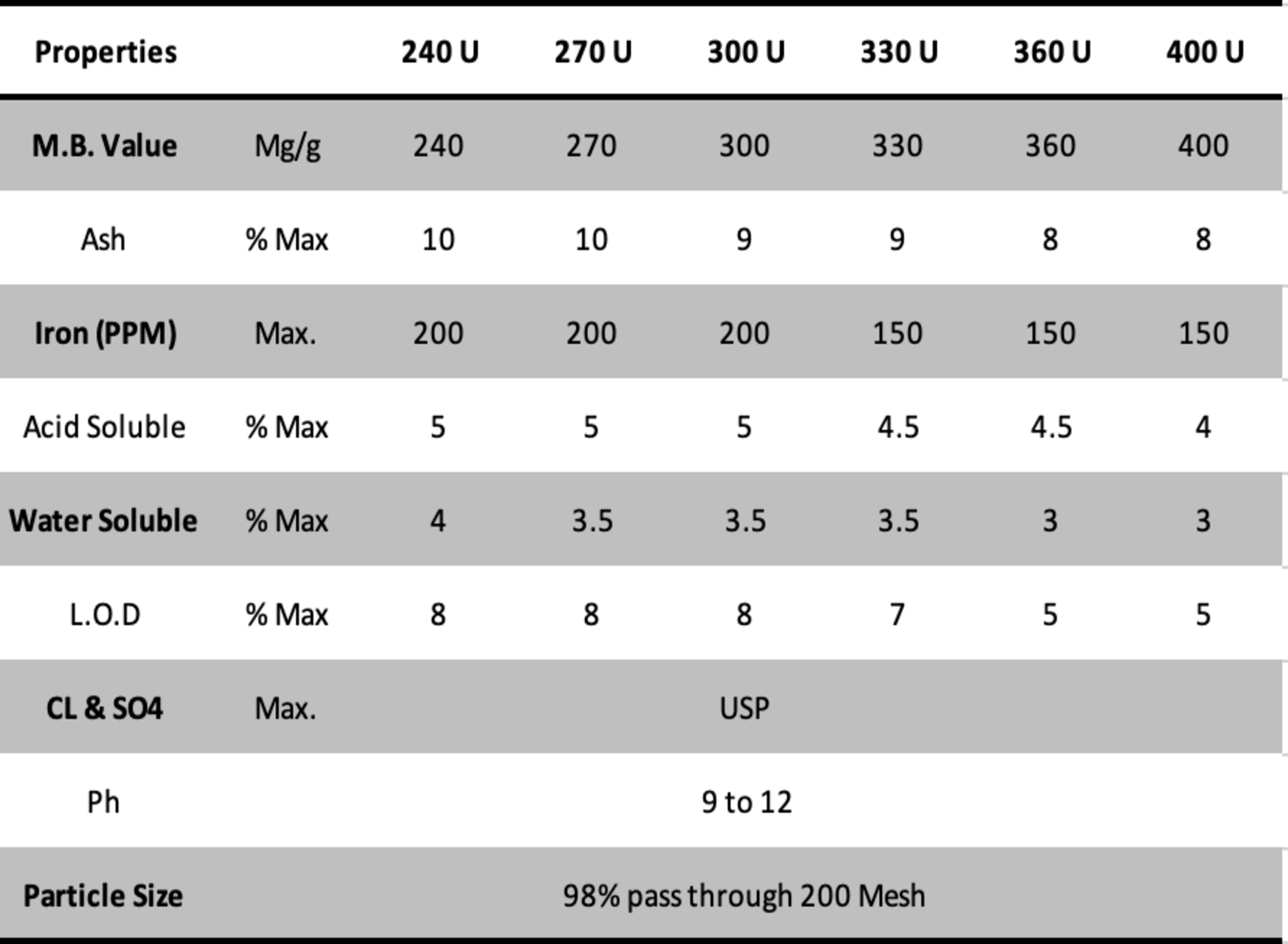

Granular Activated Carbon

Granular Activated Carbon

Washed Activated Carbon

Washed Activated Carbon

Premium Quality

Unwashed Activated Carbon

Unwashed Activated Carbon

Premium Quality

Granular Activated Carbon

Granular Activated Carbon

Premium Quality

Our Quality Policy

PROVIDING BETTER QUALITY PRODUCT AND TIMELY SERVICES.

QUALITY CHECKS ARE PERFORMED AT EACH STAGE OF THE PRODUCTION PROCESS.

TOTAL COMMITMENT FOR CUSTOMER SATISFACTION.

ENVIRONMENTAL FRIENDLY.

CONTINUOUSLY DOING R & D AND LOOKING FOR NEW INNOVATION.

GUIDING AND CO-OPERATING WITH THE CLIENTS TO MATCH THE PARAMETERS OF THE PRODUCT.

OUR POLICY IS TO REDUCE OVERHEAD EXPENSES.

WE ALWAYS STRIVE TO PROVIDE THE BEST PRODUCT AS PER THE ACTUAL SUITABILITY OF THE CLIENT. WE KEEP WORKING ON THE NEW INNOVATION, WHICH RESULTS NOT ONLY IN GROWTH AND SUCCESS OF THE COMPANY BUT ALSO STAND COMPETITIVELY IN TODAY’S WORLD. WE HAVE ESTABLISHED THE LABORATORY AT THE FACTORY ITSELF WITH THE QUALIFIED TECHNICAL PERSONNEL. OUR R & D KEEPS ON GOING FOR THE NEW TECHNOLOGICAL DEVELOPMENT. FURTHERMORE, SAMPLES OF OUR CLIENTS ARE COLLECTED AND TESTED IN THE LAB. AND ON THE BASIS OF THE SAMPLE’S QUALITY AND GRADE REQUIREMENT, WE RECOM- MEND CLIENTS OUR PRODUCTS AS PER THEIR PARAMETERS.

Manufacturing Process

THE MAJORITY OF ACTIVATED CARBON USED THROUGHOUT THE WORLD IS PRODUCED BY STEAM ACTIVATION. STEAM ACTIVATED CARBON IS PRODUCED BY TWO STAGE PROCESS. FIRSTLY THE MATERIAL IS CARBONIZED AND COKE IS PRODUCED. THE PORES OF PRODUCED COKE ARE SMALL; HENCE, THE NEXT STAGE IS A PROCESS OF ENLARGING THE PORE STRUCTURE SO THAT AN ACCESSIBLE INTERNAL SURFACE IS CREATED. THIS IS ACHIEVED BY REACTING SEMI PRODUCT WITH STEAM AT TEMPERATURE BETWEEN 900 and 1100 C. AT THIS TEMPERATURE RATE DETERMINATION FACTOR IS THE CHEMICAL REACTION BETWEEN STEAM AND CARBON. THIS REACTION TAKES PLACE AT THE INTERNAL SURFACE OF THE CARBON REMOVING CARBON FROM THE PORE WALLS AND THEREBY ENLARGING THEM. OPENING UP THE PORE STRUCTURE IS COSTLY AS THE YIELD DECREASES AND EXTRA HEAT IS REQUIRED. E.G. IN THE PURIFICATION OF WATER FOR THE ADSORPTION OF SMALL MOLECULES FROM SOLUTION. THIS CARBON IS CHEAPER COMPARE TO SUGAR DECOLORIZING CARBON WHERE LARGE MOLECULES ARE TO BE REMOVED. THUS, STEAM ACTIVATION PROCESS ALLOWS THE PORE SIZE TO BE ALTERED AND FINALLY CARBON CAN BE MADE TO SUIT DIFFERENT PURPOSES.

CHEMICAL ACTIVATED CARBON ARE PRODUCED BY MIXING CHEMICAL WITH A CARBONACEOUS MATERIAL USUALLY WOOD AND CARBONIZING THE MIXTURE. TEMPERATURE IS LOW, E.G. 400C-500C. CHEMICAL NORMALLY USED ARE PHOSPHORIC ACID AND ZINC CHLORIDE, WHICH OPEN UP THE CELLULOSE STRUCTURE OF WOOD. DURING CARBONIZATION THIS CHEMICAL ACTS AS A SUPPORT. PRESENCE OF CHEMICALS ALSO REDUCES TAR FORMATION AND LEADS TO A HIGHER YIELD. THE PHOSPHORIC ACID ACTIVATED CARBONS ARE ITSELF ACID WASHED CARBONS BUT DO NOT HAVE QUITE HIGH PURITY AS THE SPECIFICALLY ACID WASHED STEAM ACTIVATED CARBONS, AS THEY CONTAINS SMALL AMOUNT OF RESIDUAL PHOSPHATES. THE USE OF ZINC CHLORIDE AS AN ACTIVATING AGENT IS DECREASING BECAUSE OF THE ENVIRONMENT PROBLEMS AND FINAL PRODUCT CONTAINS RESIDUAL ZINC, WHICH IS UNDESIRABLE IN MANY APPLICATIONS.

Some Applications

Industrial

PHARMACEUTICAL AND BULK DRUG INDUSTRIES.

DEODORIZATION OF GELATIN AND LIQUEFIED PETROLEUM JELLY.

SUGAR INDUSTRIES.

Water-Base

WATER FILTER.

ABSORPTION OF ORGANIC MATTER.

PURIFICATION OF DRINKING WATER.

Gas-Base

GOLD RECOVERY.

THERMAL & NUCLEAR POWER STATION.

GAS MASKS FILTERS.

Contact

MR. NAVIN AGRAWAL (M) +919327008652

MR MAHESH AGRAWAL (M) +919016095722

MR. YASH AGRAWAL (M) 7043514801

32, NUTAN CLOTH MARKET, O/S. RAIPUR GATE, AHMEDABAD – 380 022 (GUJARAT), INDIA

info@technocarbonindustries.com